Deep groove ball bearings are a type of rolling-element bearing that are used in a variety of applications. They are the most common type of bearing and can support both radial and axial loads. While they are very versatile, there are still many things that you may not know about deep groove ball bearings. In this blog post, we will explore five of them. From their history to their use in electric vehicles, read on to learn more about these interesting components.

What is a deep groove ball bearing?

Deep groove ball bearings are the most common type of bearing, and are used in a wide variety of applications. They are designed to accommodate both radial and axial loads, and can operate at high speeds.

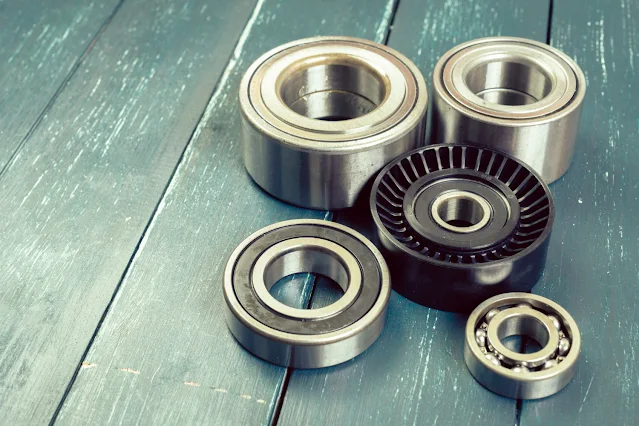

These bearings have deep, circular grooves in the outer ring that hold the balls in place, and a smaller inner ring that fits inside the shaft. The balls are made of steel and rotate freely between the grooves. When a load is applied to the bearing, the balls distribute the load evenly throughout the bearing.

Deep groove ball bearings are simple in design, durable, and require little maintenance. They can be used in a wide variety of applications, including electric motors, pumps, fans, bicycles, and automobiles.

How do deep groove ball bearings work?

Deep groove ball bearings are the most common type of bearing, and are typically used in rotary applications. The bearing consists of a series of balls held between two races, and the rotation of the shaft or other element causes the balls to rotate as well. This action reduces friction and allows for smooth operation.

What are the benefits of using deep groove ball bearings?

Deep groove ball bearings are the most commonly used type of rolling bearing. Their popularity is due to their versatility and low cost.

Deep groove ball bearings are able to accommodate radial loads and axial loads in both directions. They are easy to mount and require little maintenance. Deep groove ball bearings can reach very high speeds, making them ideal for high-speed applications.

Deep groove ball bearings typically have a lower load capacity than other types of rolling bearings. However, they are capable of operating at high speeds and can be found in a variety of applications.

What are some common applications for deep groove ball bearings?

There are many common applications for deep groove ball bearings. They are used in electric motors, pumps, fans, and in many other types of machinery. They are also used in bicycles, skateboards, and rollerblades.

How can you maintain your deep groove ball bearings?

There are a few things you can do to maintain your deep groove ball bearings and keep them in good working order. First, make sure to keep them clean and free of debris. You can do this by using a soft cloth or brush to lightly remove any dirt or grime that has built up on the surface. Additionally, it's important to keep these bearings lubricated with a high-quality grease or oil. This will help reduce friction and wear, and extend the life of your bearings. Finally, be sure to check the seals regularly for any damage or leaks, and replace them as needed. By following these simple tips, you can ensure that your deep groove ball bearings will last for many years to come.

Conclusion

Deep groove ball bearings are an important part of many machines and devices, but there is still a lot that people don't know about them. We hope that this article has shed some light on the topic and shown you just how versatile and useful these bearings can be. If you're in need of bearings for your next project, be sure to check out our selection of deep groove ball bearings. We have a wide variety of sizes and styles to choose from, so you're sure to find the perfect match for your needs.

References

- 10 Best (& Worst) Skateboard Bearings | Cheaper Is Better .... (2022). Retrieved on December 1, 2022, from https://www.skateboardershq.com/best-skateboard-bearings/. Bushing or Bearing, what's the difference?. (2022).

- Retrieved on December 1, 2022, from https://www.bearings.saint-gobain.com/media-center/blog/guide-bearings-and-bushings.

- Does Your Application Need Radial Bearings?. (2022). Retrieved on December 1, 2022, from https://www.gmnbt.com/ball-bearing-guide/does-your-application-need-radial-bearings/.

- What Some Chinese Bearing Suppliers Don't Want You To Know!. (2022). Retrieved on December 1, 2022, from https://www.ktaiballbearing.com/what-some-chinese-bearing-suppliers-dont-want-you-to-know/.

Reykindo is B to B Supplier of Bearings for MRO Industrial Factory Needs Throughout Indonesia

There are many types of bearings, but deep groove ball bearings are among the most common. They are used in a wide variety of applications, including automotive, aerospace, and manufacturing.

Deep groove ball bearings are composed of an inner and outer ring, with a set of balls in between. The balls are made of steel and rotate on a set of races. The inner race is typically mounted on a shaft, while the outer race is held in place by a housing or other support structure.

Deep groove ball bearings can handle both radial and axial loads, making them suitable for a wide range of applications. They are widely used in gearboxes, pumps, fans, and other mechanical equipment.

Deep groove ball bearings are available in a variety of sizes and designs to meet the needs of different applications. Some common designations include single-row, double-row, and angular contact bearings.